By Sahar ElKabbash

We’ve all read the news from different countries around the world about a shortage of personal protective equipment (PPE) and how frontline workers and healthcare professionals are risking their lives sometimes without being given the right equipment.

Thankfully Qatar has not faced that same problem.

Part of that is due to the collaboration of civil society and the measures taken by the government. One great example of that can be found at Virginia Commonwealth University in Qatar Foundation, which has been using its facilities and materials to produce one of the most important components of PPE — face masks.

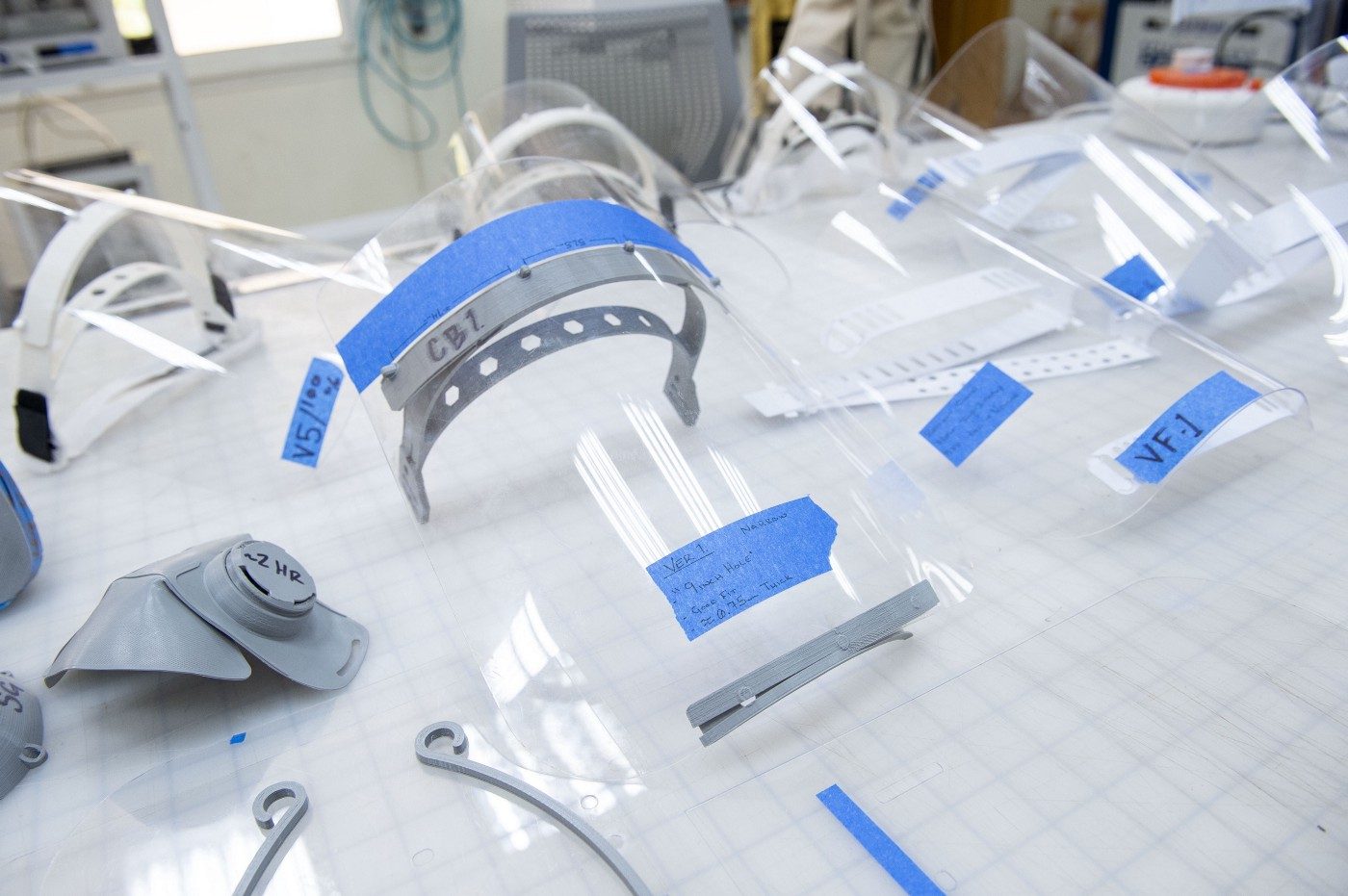

VCUarts Qatar’s Fabrication Lab (FabLab) team collaborated with a group of designers from Chicago to build on the original design of face shields by high school teacher Jeff Solin. Using two kinds of thermoplastics, aluminum, and velcro, the designers created an inexpensive piece of PPE to be used by healthcare workers.

The team also worked with QBIC (Qatar Business Incubation Center), which had already been creating PPE for the Qatari market.

To ensure their masks met the required medical standards, Qatar Foundation Primary Healthcare Center’s Dr. Nandakumar G. Pillai provided the team with feedback on the prototypes before final production began.

Doha News spoke to Chris Buchakjian, the Digital Fabrication Lab & Woodshop Coordinator at VCUarts Qatar, who told us that the team does not intend to sell the products for profit. “Wherever there is a need, and as long as we have materials, we will keep producing.”

They are currently providing the face shields to healthcare workers at the Qatar Foundation clinic but are open to fill a supply gap and offer their products to any medical facility if the need arises.